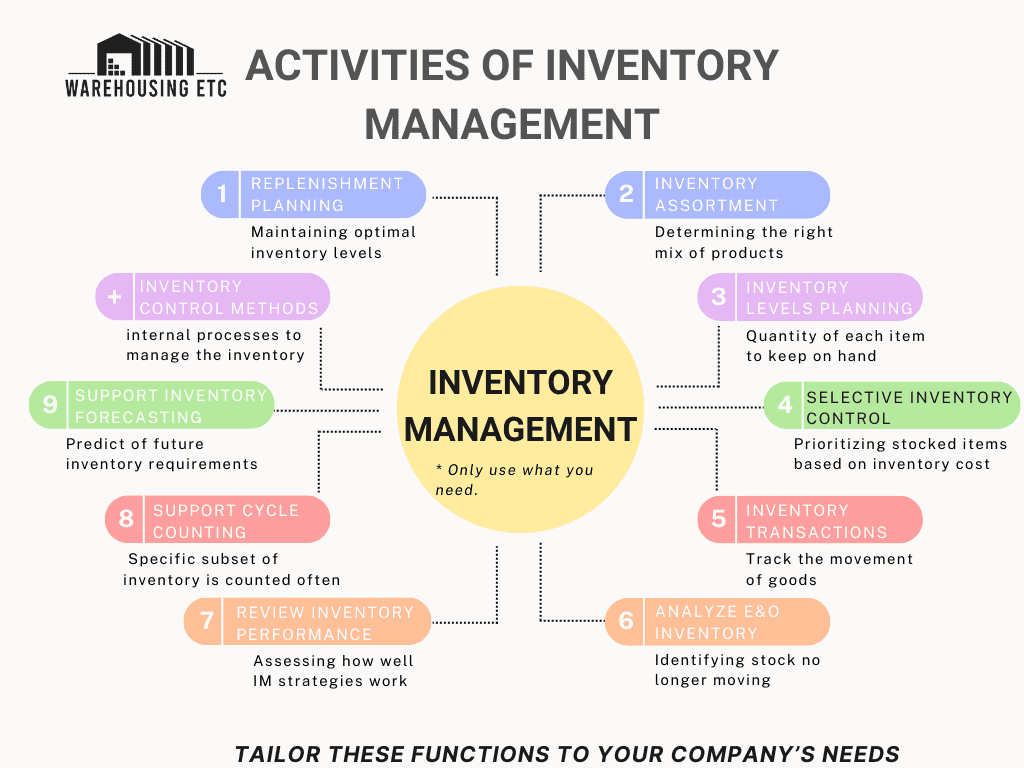

Business Inventory Management: Key to Efficient Operations and Growth

Effective inventory management is the backbone of any successful business, especially for those dealing with physical products. Whether you run a small business or a large corporation, managing inventory efficiently ensures smooth operations, cost-effectiveness, and timely deliveries. With the right strategies and tools, businesses can avoid stockouts, overstocking, and financial inefficiencies.

:max_bytes(150000):strip_icc()/inventory-management-8595e839c2884128997ca77f00a8da2b.jpg)

Why Is Inventory Management Crucial for Business?

Inventory management is more than just tracking stock. It’s a critical component of your overall supply chain that affects your ability to meet customer demand, maintain operational efficiency, and boost profitability.

1. Maintaining Optimal Stock Levels

The primary purpose of inventory management is to ensure you have the right amount of stock at the right time. Too much stock can tie up valuable capital, while too little stock can lead to missed sales opportunities. Striking the right balance is crucial for operational efficiency and financial health.

2. Improving Cash Flow

Effective inventory management can improve your cash flow by ensuring that you don’t overstock or understock. Overbuying inventory ties up cash that could be better used elsewhere in the business, while underbuying can lead to stockouts and lost sales. Efficient inventory control helps maintain a steady cash flow, essential for business survival.

3. Reducing Operational Costs

Inventory management isn’t just about tracking stock; it also involves minimizing the cost of storing, managing, and transporting goods. By optimizing your inventory, you can reduce storage fees, shipping costs, and the risk of obsolescence.

4. Enhancing Customer Satisfaction

Having the right products available when customers need them is crucial to customer satisfaction. Effective inventory management ensures that your business is always ready to fulfill orders on time, helping build customer trust and loyalty.

Key Strategies for Effective Inventory Management

Implementing the right inventory management strategies can help your business streamline operations, cut costs, and enhance customer satisfaction. Here are some of the most effective strategies:

1. Just-In-Time (JIT) Inventory

JIT is a strategy where inventory is ordered and received only when needed in the production process, reducing storage costs and minimizing the risk of overstocking. This approach requires accurate forecasting and a reliable supply chain but can significantly improve cash flow and reduce waste.

2. ABC Analysis

ABC analysis categorizes inventory into three groups based on value and turnover rate.

-

A items are high-value items with low sales frequency.

-

B items are moderate in both value and turnover.

-

C items are low-value items with high sales frequency.

By categorizing inventory, businesses can prioritize the management of high-value or critical items.

3. Stock Replenishment Strategies

Regular stock replenishment is crucial to maintaining optimal stock levels. This can be achieved through various methods, such as automatic reorder points, safety stock, or predictive analytics to forecast demand.

4. Using Technology for Inventory Tracking

Implementing inventory management software can help businesses automate stock tracking, reorder alerts, and reporting. Technology reduces human error, speeds up processes, and allows for real-time visibility into inventory levels, helping you make informed decisions.

5. Barcode and RFID Systems

Barcodes and RFID tags help track inventory automatically and reduce errors associated with manual tracking. These systems enable quick scanning and accurate inventory counts, saving time and reducing human error.

Benefits of Using Inventory Management Software

Inventory management software offers a wide range of benefits, especially as your business grows and inventory complexity increases.

1. Improved Efficiency

Software solutions automate key processes, such as tracking stock levels, placing orders, and generating reports. This reduces the manual effort involved and speeds up operations.

2. Real-Time Tracking

With inventory management software, you can monitor stock levels in real-time. This helps identify issues, such as stockouts or overstocking, before they become significant problems.

3. Better Forecasting

Advanced inventory management systems use historical sales data and market trends to predict future demand, making it easier to adjust stock levels accordingly.

4. Integration with Other Business Systems

Many inventory management tools integrate seamlessly with other business systems, such as accounting, sales, and e-commerce platforms. This integration ensures consistency across all your business functions and saves time on manual data entry.

5. Cost Control

By providing insights into which products are selling the most, inventory software helps businesses focus on fast-moving items and reduce spending on slow-moving stock.

Common Challenges in Inventory Management

While effective inventory management can provide significant benefits, it’s not without challenges. Recognizing these challenges can help you prepare solutions in advance.

1. Inventory Overstocking

Overstocking can lead to higher storage costs, obsolete products, and cash flow problems. This issue often arises due to poor demand forecasting or inefficient stock replenishment practices.

2. Stockouts and Lost Sales

On the flip side, stockouts can result in missed sales opportunities and unhappy customers. Managing stockouts requires accurate demand forecasting and quick response times to reorder stock.

3. Poor Visibility into Inventory Levels

Lack of visibility can lead to errors in stock counts and delays in order fulfillment. Real-time inventory tracking systems can help reduce this issue by providing a centralized view of stock across multiple locations.

4. Complexity in Managing Multiple Locations

For businesses with multiple warehouses or retail locations, keeping track of inventory across different sites can become complex. Multi-location inventory management software can help streamline this process and reduce the risk of errors.

How to Track Inventory Effectively

Effective inventory tracking is key to ensuring that your stock levels are accurate and up-to-date. Here’s how you can track inventory efficiently:

1. Set Reorder Points

Establish minimum stock levels at which new orders should be placed. This ensures that you always have enough stock to meet demand without overstocking.

2. Conduct Regular Stock Audits

Regular audits help ensure that your physical inventory matches your system records. Scheduled stock counts, whether monthly or quarterly, help identify discrepancies early.

3. Implement Real-Time Tracking

Use barcode scanners, RFID tags, or inventory management software to track your stock in real-time. Real-time tracking helps you stay ahead of demand and reduce stock discrepancies.

FAQs About Business Inventory Management

Q1: What is the best way to prevent stockouts?

To prevent stockouts, maintain accurate demand forecasts, set appropriate reorder points, and use inventory management software for real-time tracking. Consider implementing a Just-In-Time inventory strategy for efficient stock replenishment.

Q2: How can I reduce inventory holding costs?

To reduce inventory holding costs, focus on optimizing stock levels. Implement strategies like ABC analysis, JIT inventory, and automated stock replenishment to ensure you’re not overstocking.

Q3: Is inventory management software expensive?

Inventory management software comes in a range of pricing models, from affordable options for small businesses to advanced solutions for larger enterprises. The ROI from improved efficiency and cost savings typically outweighs the initial investment.

Q4: How do I manage inventory across multiple locations?

Use multi-location inventory management software to track and manage stock across different locations. This software ensures that inventory levels are consistent and helps avoid stockouts or overstocking at any given location.

Conclusion

Effective business inventory management is a cornerstone of successful operations. By implementing the right strategies, tools, and technologies, you can optimize your inventory, reduce costs, improve customer satisfaction, and drive business growth. Whether you use inventory management software, JIT inventory, or ABC analysis, the goal is always to maintain the right balance of stock to meet demand efficiently and cost-effectively.